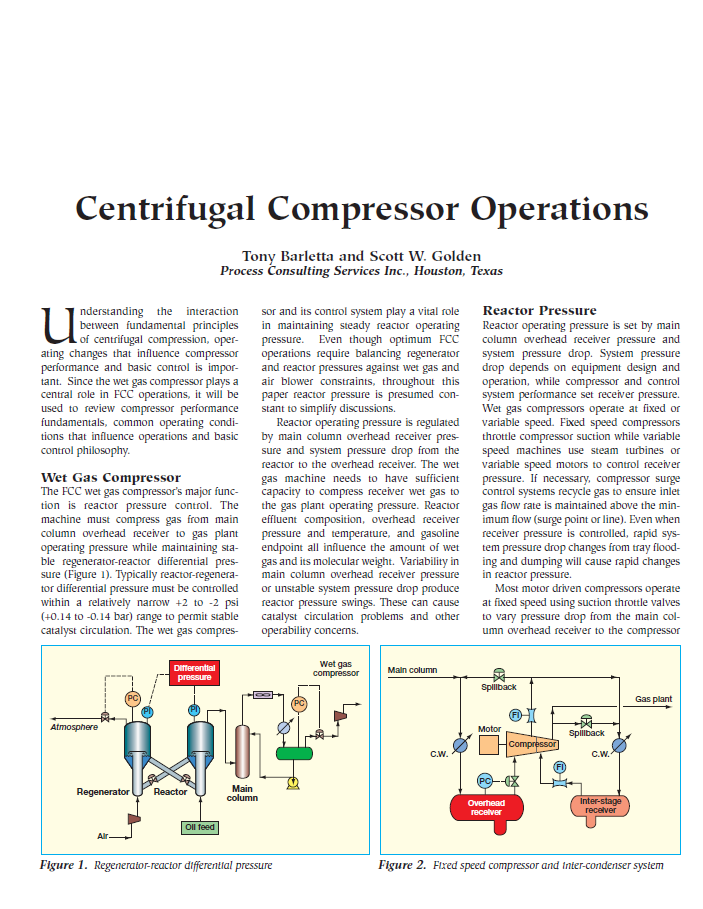

The wet gas compressor is used as an example in this article reviewing compressor performance, operating conditions and basic control philosophy - an aid to understanding the interactions influencing compressor performance and control.

Read MoreThe design, detailed engineering and installation of one revamp took just four-and-a-half months. Unit feed rate, product recovery and product quality objectives were all met after the revamp.

Read MoreMeeting lower gasoline product sulfur levels requires understanding sulfur distribution and species as function of the FCC gasoline boiling range. Gasoline pool sulfur limits can be achieved by minimizing contaminants in the cat feed hydrotreater (CFHT) feed and improving fractionation between gasoline and LCO. In many cases these options are much less expensive than designing the CFHT based on high-contaminant feed resulting from poor distillation unit performance.

Read MoreFCC debutanizer reboiler shell-side fouling causes unscheduled outages and can make bundle removal difficult or impossible. Expensive solutions such as the addition of a parallel reboiler system only treat the symptoms, not the causes, of the problem. FCC debutanizer fouling is caused by di-olefin polymerization and poor exchanger design. Improved exchanger design has eliminated unscheduled outages in several FCC’s.

Read MoreUnderstanding how FCC and Delayed Coker wet gas compressor capacity is impacted by system pressure drop allows low cost changes to be made without expensive compressor modifications. In many instances high pressure drop caused by poor system design reduces unit capacity, lowers conversion, or raises column operating pressure. This article presents several solutions for increasing compressor capacity through inexpensive process system modifications.

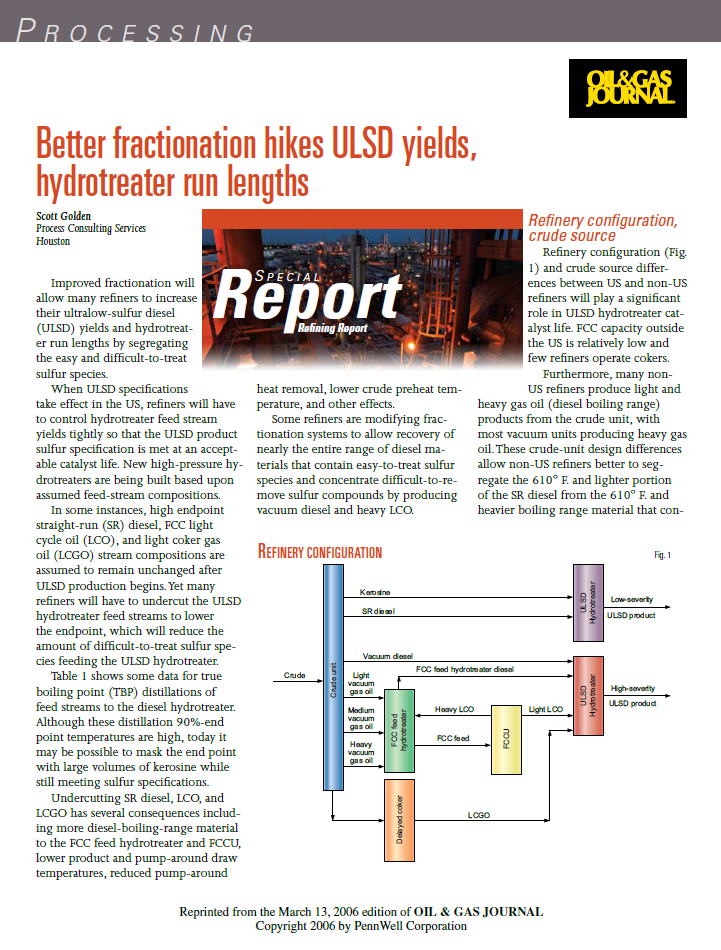

Read MoreImproved CDU, FCC and Coker main column fractionation maximizes diesel boiling range yields while eliminating hard-to-treat sulfur components from the hydrotreater feed. Hydrotreater run lengths can be materially improved by improving the segregation of easy-to-treat and hard-to-treat sulfur species in upstream distillation units.

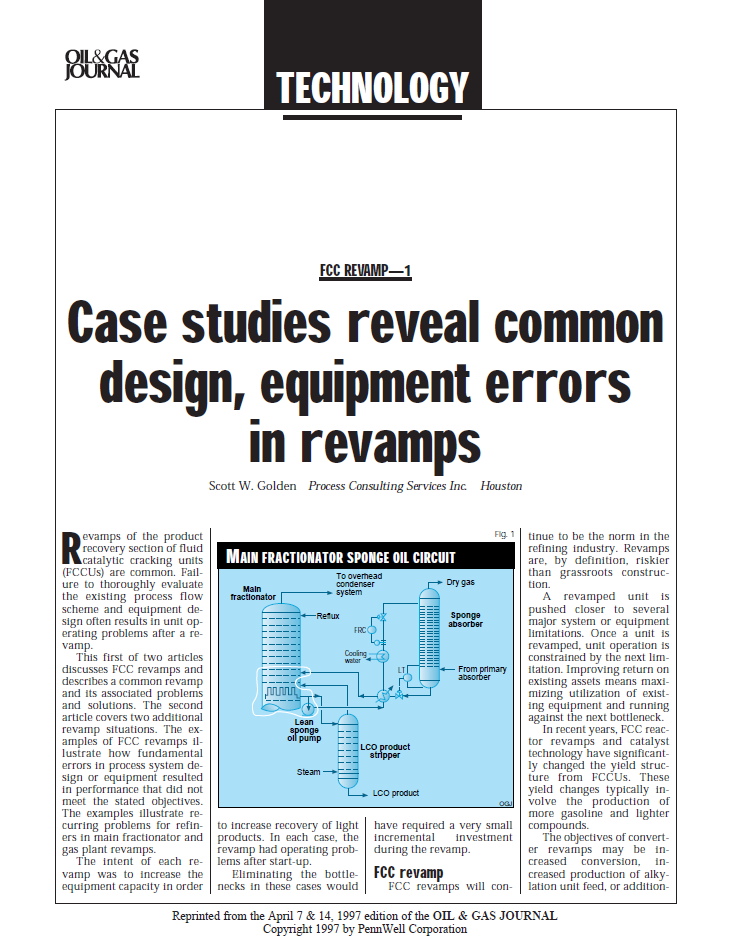

Read MoreRevamps of the product recovery section of fluid catalytic cracking units (FCCUs) are common. Failure to thoroughly evaluate the existing process flow scheme and equipment design often results in unit operating problems after a revamp.

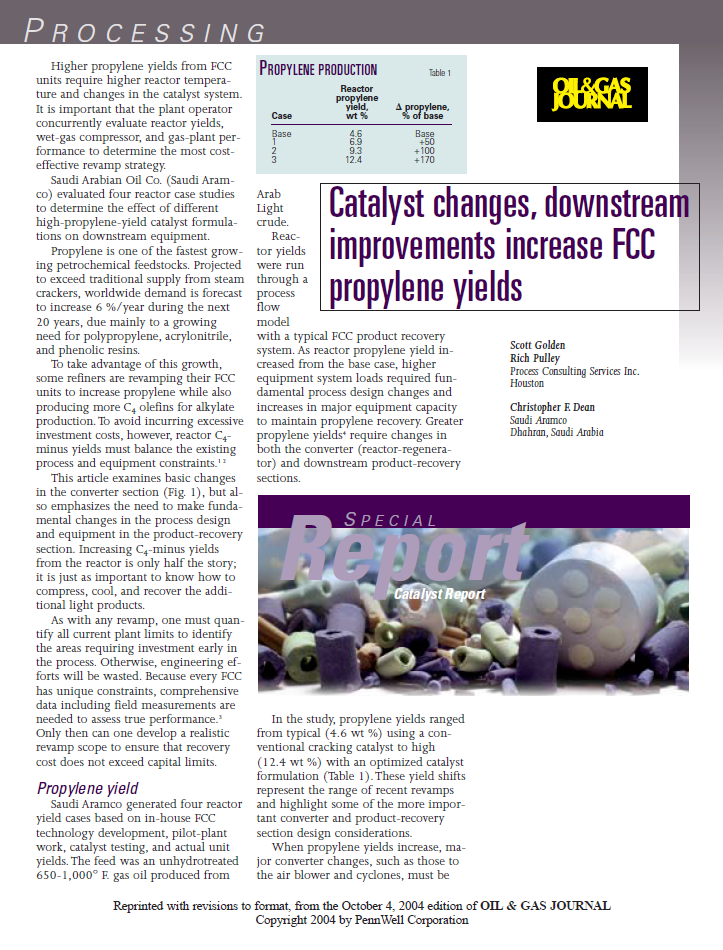

Read MoreIncreasing propylene yields from an FCC can be an attractive alternative to a steam cracker. Reactor and catalyst system changes can lead to much higher propylene yields than conventional FCC operations. Increasing propylene yields place additional demands on the gas plant, which need to be evaluated as part of the decision-making process. Otherwise valuable C4- products could be lost to fuel gas.

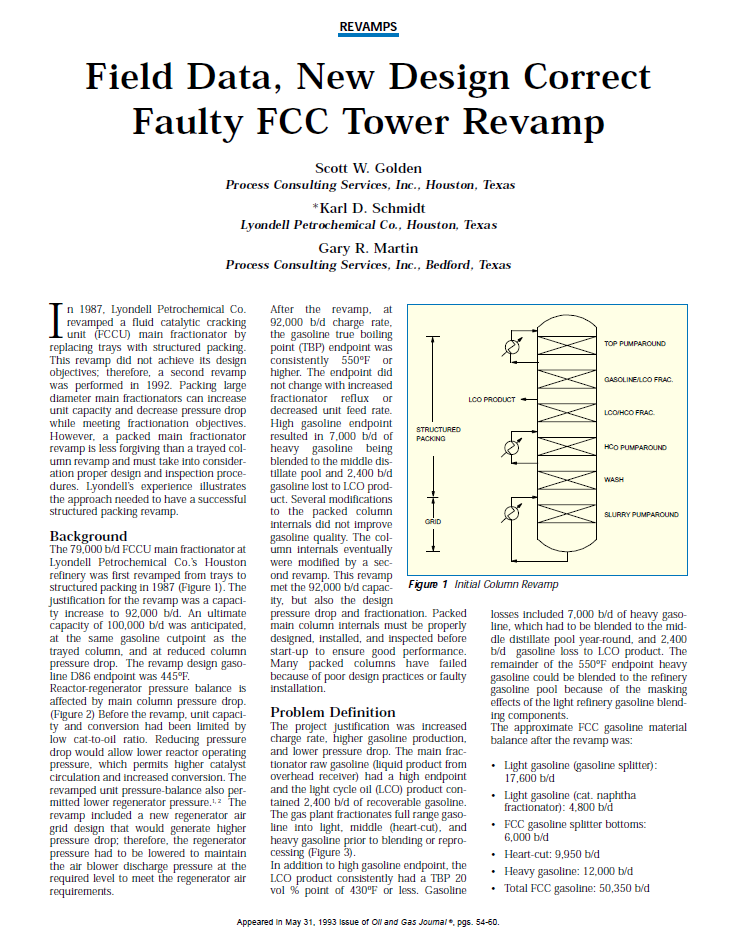

Read MoreA large US Gulf Coast refinery had poor fractionation in their FCC main column after replacing trays with structured packing. Large amounts of gasoline were being downgraded to LCO because low cost liquid distributors were used. Packed main fractionators offer theoretical improvements, but are less forgiving than trayed columns so proper design and inspection are paramount. Once the design errors were corrected the fractionating problems were eliminated and unit goals were achieved.

Read MoreCoking in petroleum refinery main fractionators causes unscheduled shutdowns and significant production losses. Coking, however, is not inevitable. It is a function of the process and equipment design and operating errors. If the equipment is not designed properly, the unit will coke, regardless of how it is operated.

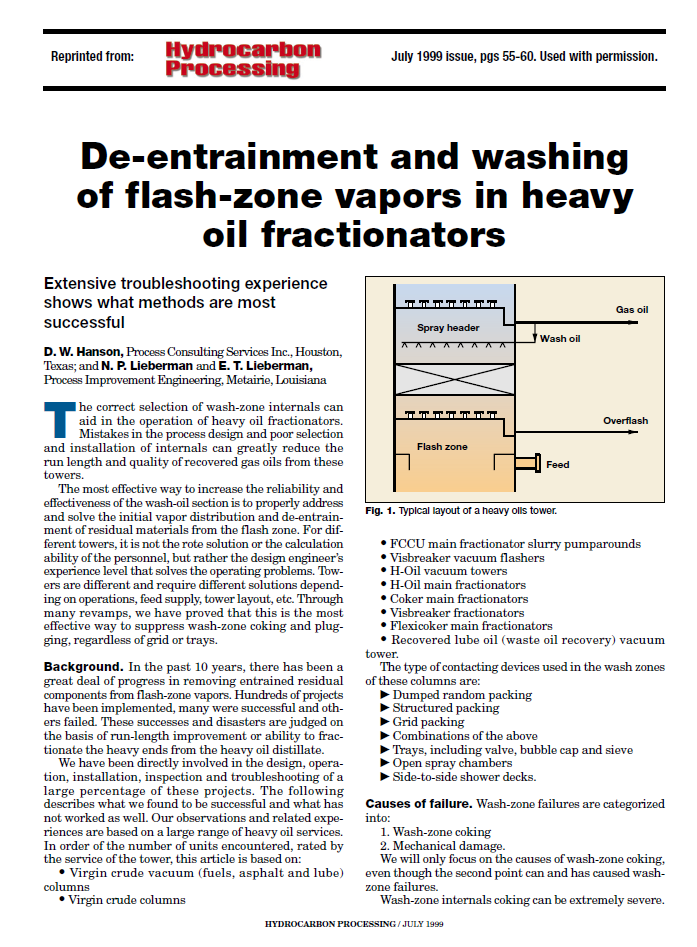

Read MoreExtensive troubleshooting experience shows what methods are most successful.

Read MoreUnit charge rate and reactor conversion were increased by elimination of stripper column flooding. Chemical-grade propylene specifications were met and C2 excursions in mixed C2/C3 streams were eliminated.

Read MoreStructured packing can influence unit pressure profiles and increase capacity.

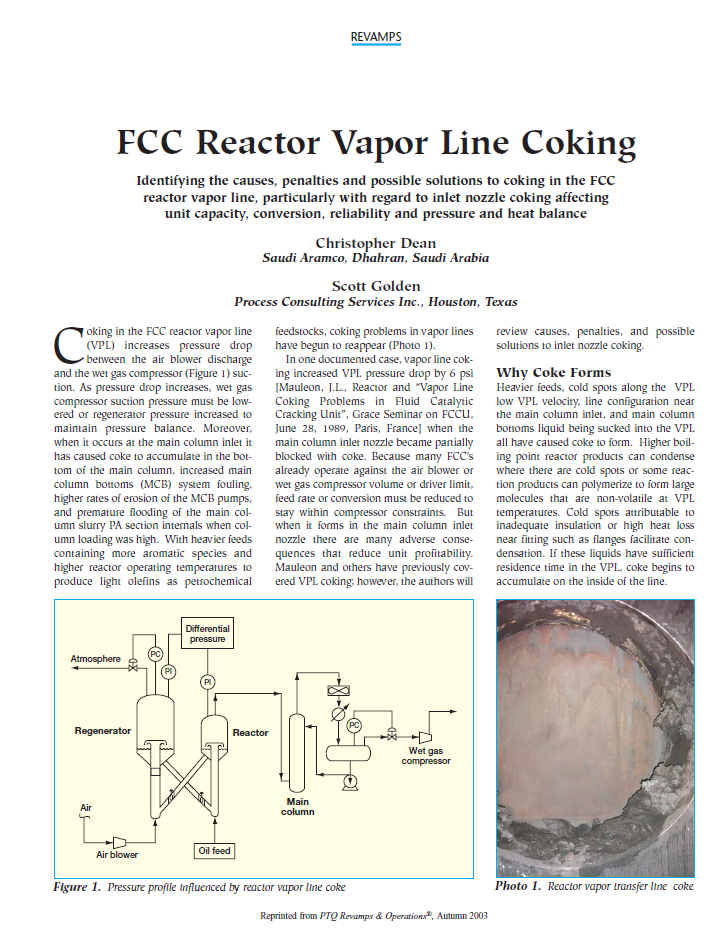

Read MoreIdentifying the causes, penalties and possible solutions to coking in the FCC reactor vapor line, particularly with regard to inlet nozzle coking affecting unit capacity, conversion, reliability and pressure and heat balance.

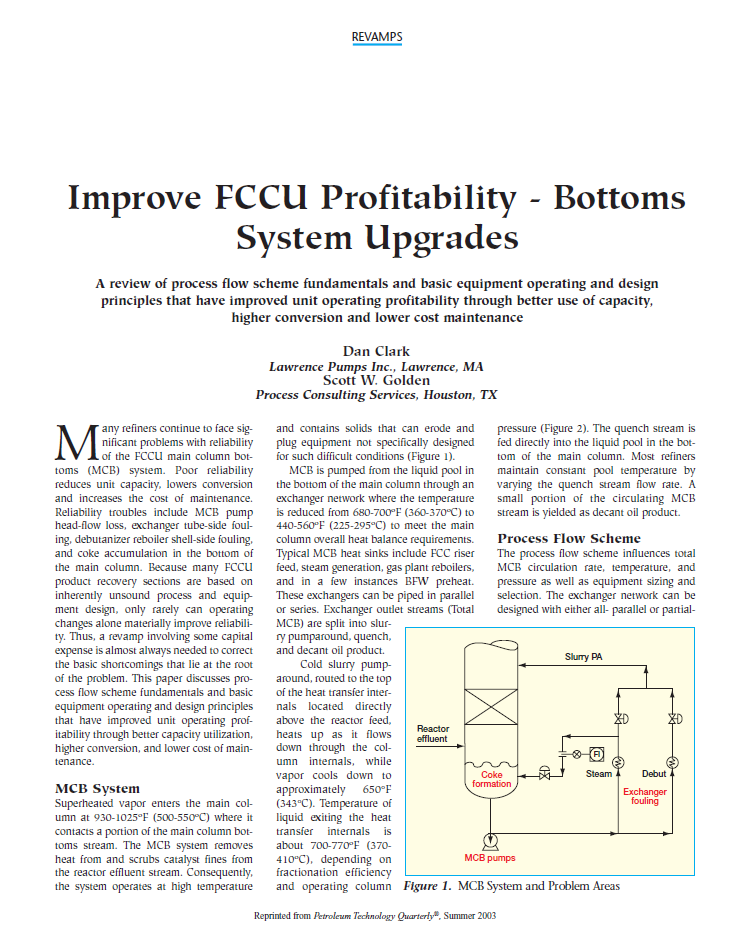

Read MoreA review of process flow scheme fundamentals and basic equipment operating and design principles that have improved unit operating profitability through better use of capacity, higher conversion and lower cost maintenance.

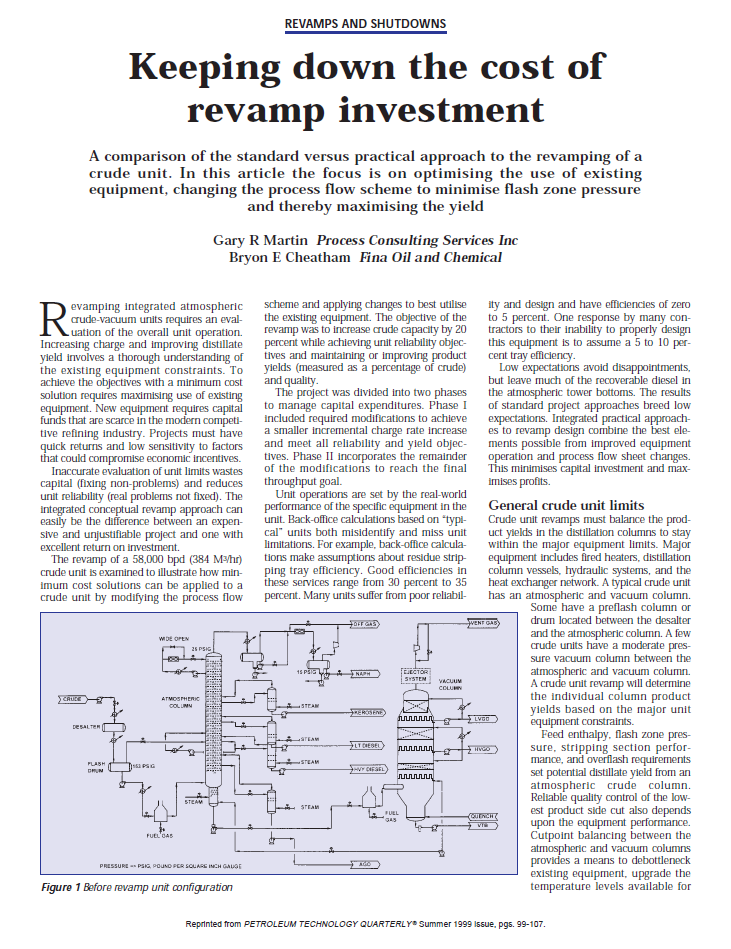

Read MoreA comparison of the standard versus practical approach to the revamping of a crude unit. In this article the focus is on optimising the use of existing equipment, changing the process flow scheme to minimise flash zone pressure and thereby maximising the yield.

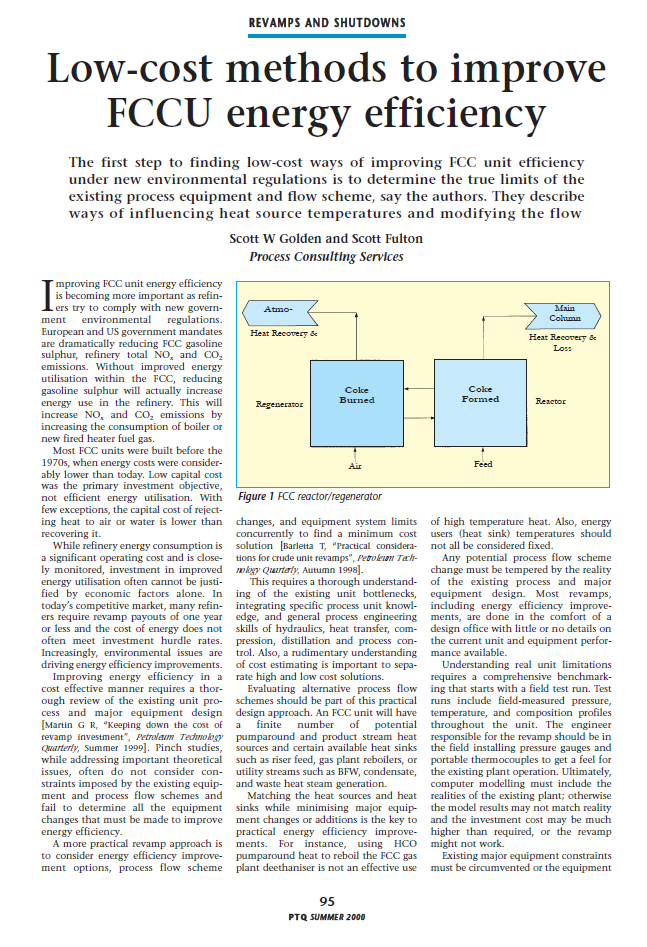

Read MoreThe first step to finding low-cost ways of improving FCC unit efficiency under new environmental regulations is to determine the true limits of the existing process equipment and flow scheme, say the authors. They describe ways of influencing heat source temperatures and modifying the flow.

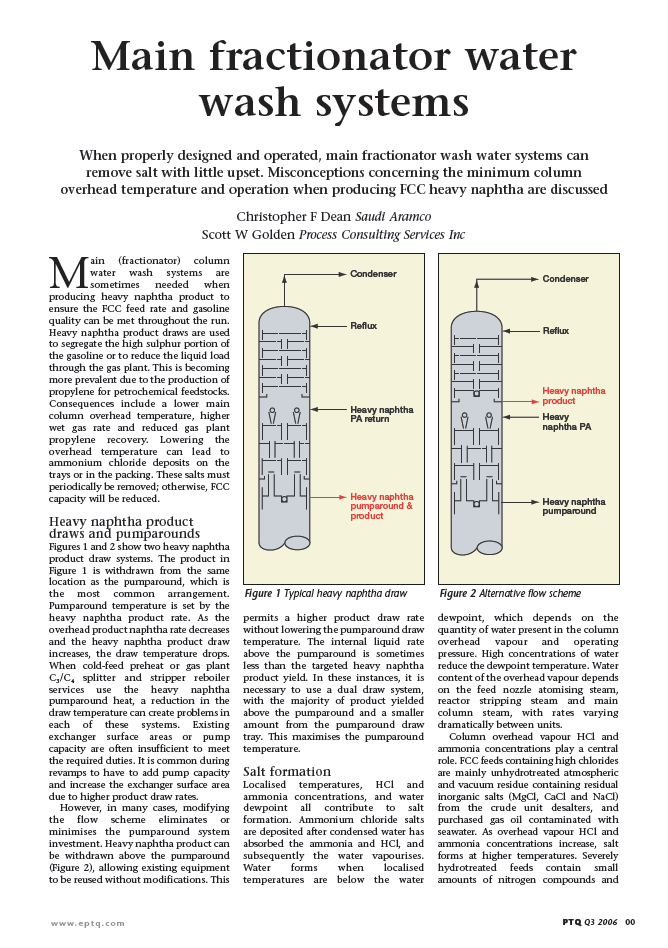

Read MoreWhen properly designer and operated, main fractionator wash water systems can remove salt with little upset. Misconceptions concerning the minimum column overhead temperature and operation when producing FCC heavy naphtha are discussed.

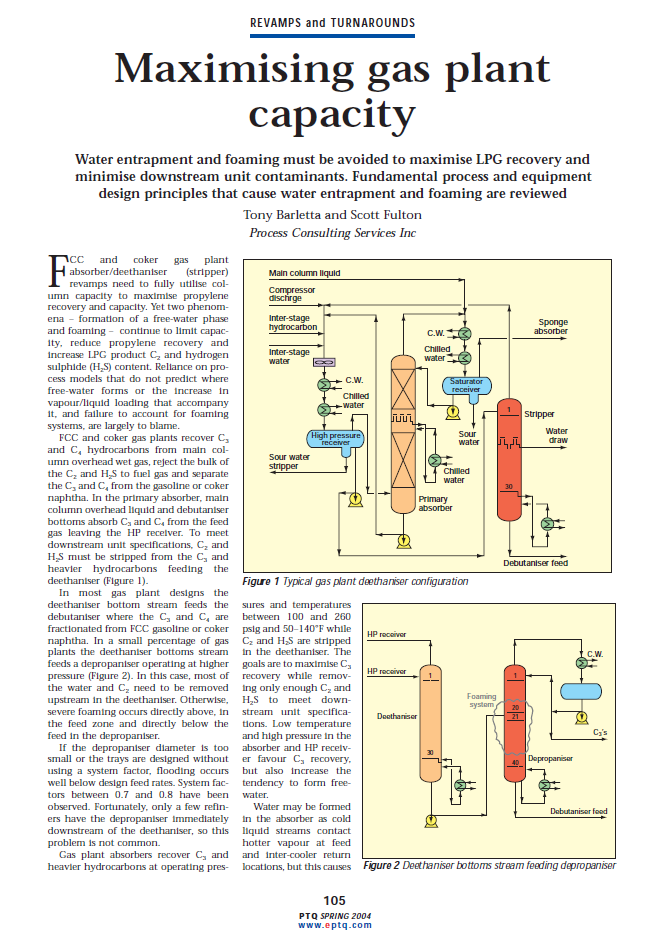

Read MoreWater entrapment and foaming must be avoided to maximize LPG recovery and minimize downstream unit contaminants. Fundamental process and equipment design principles that cause water entrapment and foaming are reviewed.

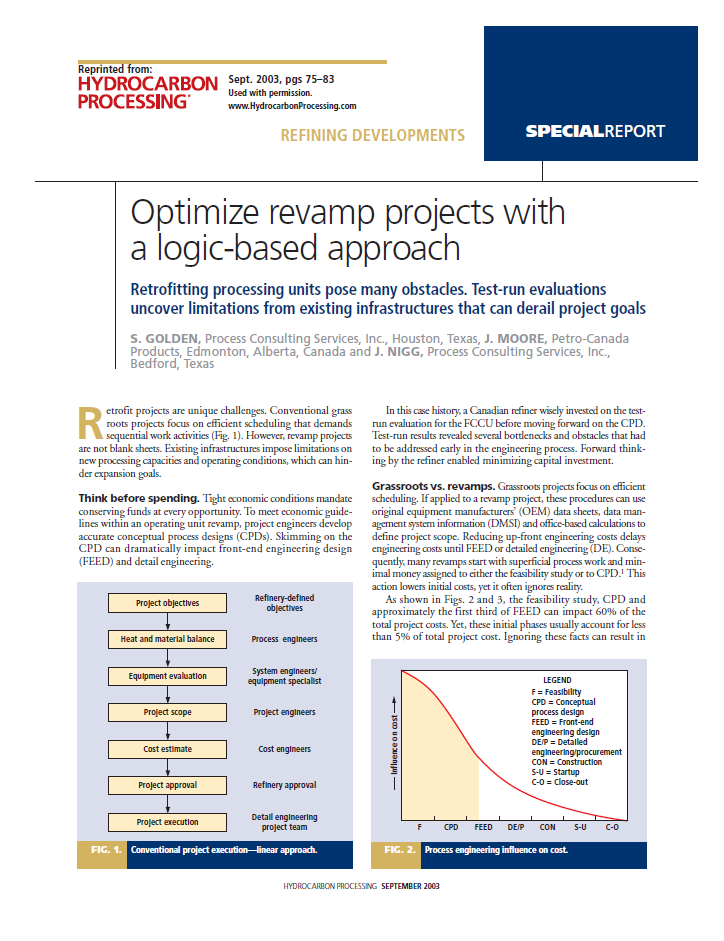

Read MoreRetrofitting processing units pose many obstacles. Test-run evaluations uncover limitations from existing infrastructures that can derail project goals.

Read More