De-entrainment and Washing of Flash-zone Vapors in Heavy Oil Fractionators

SUMMARY

Extensive troubleshooting experience shows what methods are most successful.

TEXT

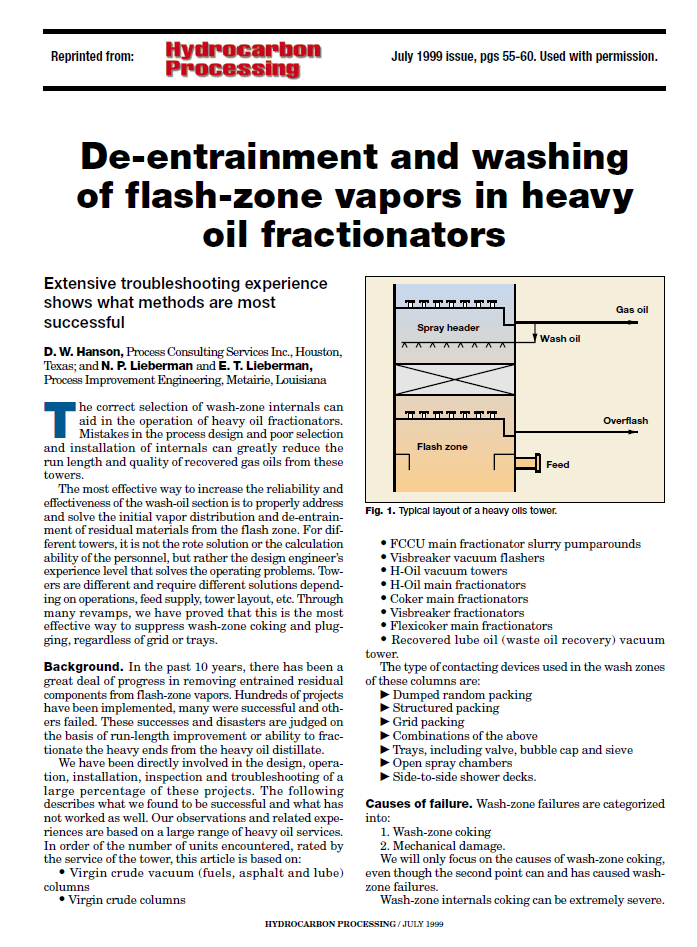

The correct selection of wash-zone internals can aid in the operation of heavy oil fractionators. Mistakes in the process design and poor selection and installation of internals can greatly reduce the run length and quality of recovered gas oils from these towers.

The most effective way to increase the reliability and effectiveness of the wash-oil section is to properly address and solve the initial vapor distribution and de-entrainment of residual materials from the flash zone. For different towers, it is not the rote solution or the calculation ability of the personnel, but rather the design engineer’s experience level that solves the operating problems. Towers are different and require different solutions depending on operations, feed supply, tower layout, etc. Through many revamps, we have proved that this is the most effective way to suppress wash-zone coking and plugging, regardless of grid or trays.

In the past 10 years, there has been a great deal of progress in removing entrained residual components from flash-zone vapors. Hundreds of projects have been implemented, many were successful and others failed...