Main Fractionator Water Wash Systems

SUMMARY

When properly designer and operated, main fractionator wash water systems can remove salt with little upset. Misconceptions concerning the minimum column overhead temperature and operation when producing FCC heavy naphtha are discussed.

TEXT

Main (fractionator) column water wash systems are sometimes needed when producing heavy naphtha product to ensure that FCC feed rate and gasoline quality can be met throughout the run. Heavy naphtha product draws are used to segregate the high sulphur portion of the gasoline or to reduce the liquid load through the gas plant. This is becoming more prevalent due to the production of propylene for petrochemical feedstocks. Consequences include a lower main column overhead temperature, higher wet gas rate and reduced gas plant propylene recovery. Lowering the overhead temperature can lead to ammonium chloride deposits on the trays or in the packing. These salts must periodically be removed; otherwise, FCC capacity will be reduced.

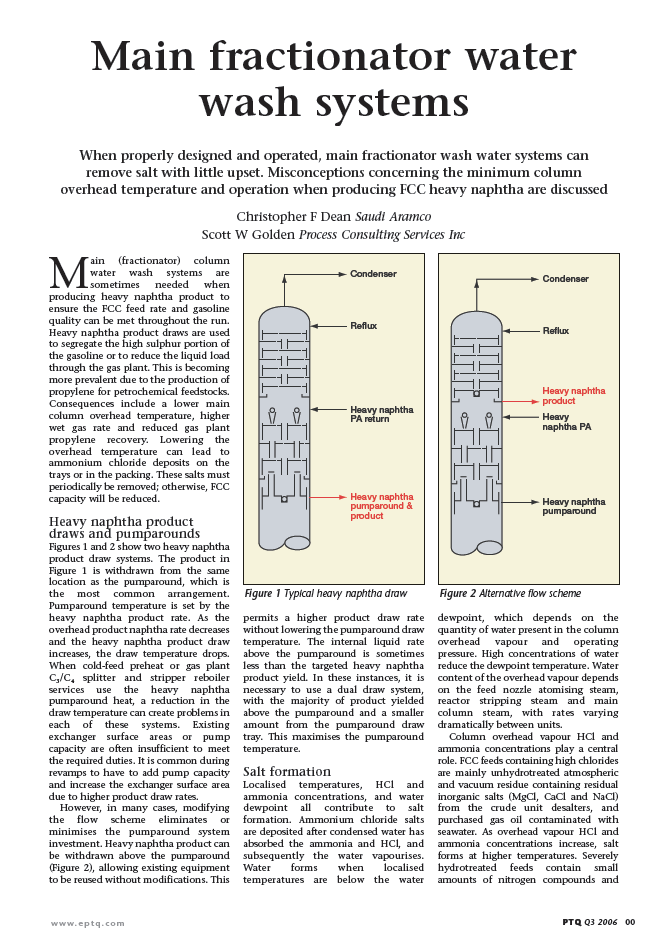

Figures 1 and 2 show two heavy naphtha product draw systems. The product in Figure 1 is withdrawn from the same location as the pumparound, which is the most common arrangement. Pumparound temperature is set by the heavy naphtha product rate. As the overhead product naphtha rate decreases and the heavy naphtha product draw increases, the draw temperature drops. When cold-feed preheat or gas plant...