FCC Gas Concentration Unit Stripper Revamp

SUMMARY

Unit charge rate and reactor conversion were increased by elimination of stripper column flooding. Chemical-grade propylene specifications were met and C2 excursions in mixed C2/C3 streams were eliminated.

TEXT

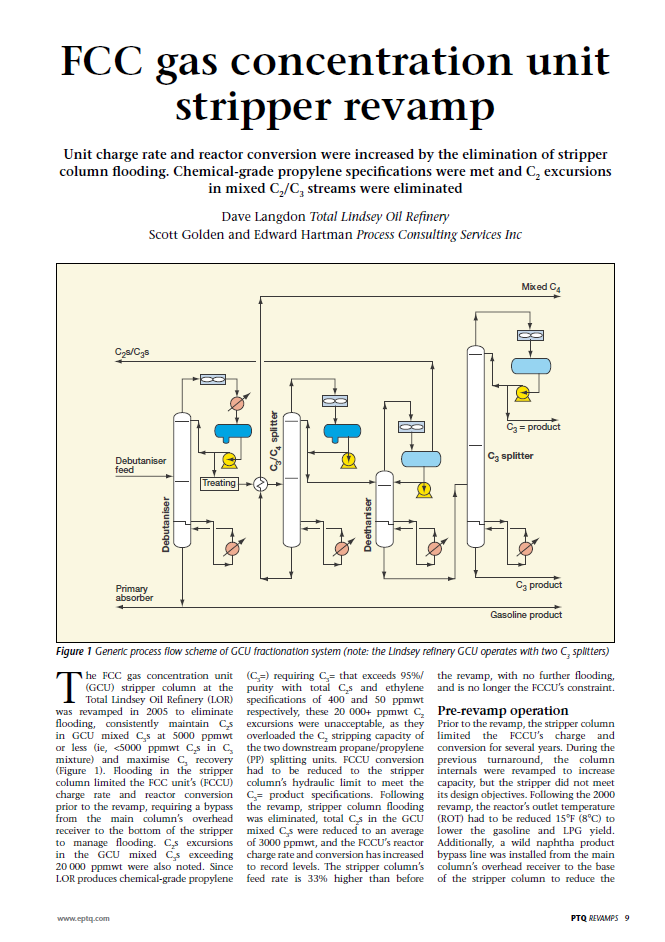

The FCC gas concentration unit (GCU) stripper column at the Total Lindsey Oil Refinery (LOR) was revamped in 2005 to eliminate flooding, consistently maintain C2s in GCU mixed C3s at 5000 ppmwt or less (ie, <5000 ppmwt C2s in C3 mixture) and maximize C3 recovery. Flooding in the stripper column limited the FCC unit’s (FCCU) charge rate and reactor conversion prior to revamp, requiring a bypass from the main column’s overhead receiver to the bottom of the stripper to manage flooding. C2s excursions in the GCU mixed C3s exceeding 20,000 ppmwt were also noted. Since LOR produces chemical-grade propylene (C3=) requiring C3= that exceeds 95%/purity with total C2s and ethylene specifications of 400 and 50 ppmwt respectively, these 20,000+ ppmwt C2 excursions were unacceptable, as they overloaded the C2 stripping capacity of the two downstream propane/propylene (PP) splitting units. FCCU conversion had to be reduced to the stripper column’s hydraulic limit to meet the C3= product specifications. Following the revamp, stripper column flooding was eliminated; total C2s in the GCU mixed C3s were reduced to an average of 3,000 ppmwt, and the FCCU’s reactor charge rate and conversion has increased to record levels. The stripper column’s feed rate is 33% higher than before the revamp, with no further flooding, and is no longer the FCCU’s constraint.

Prior to the revamp, the stripper column limited the FCCU’s charge and conversion for several years. During the previous turnaround, the column internals were revamped to increase capacity, but the stripper did not meet its design objectives. Following the 2000 revamp, the reactors outlet temperature (ROT) had to be reduced…