Diesel and VGO Recovery

SUMMARY

Fundamental design considerations influencing diesel and vacuum gas oil (VGO) recovery when revamping existing or designing grassroots crude units.

TEXT

Good fractionation is basic to achieving maximum return on every barrel of charged crude. This is so obvious that it is puzzling why some refiners ignore innovative changes to traditional crude unit design, which can increase yield of higher value streams, unload the FCC, hydrotreater and coker, permit more efficient use of energy, and allow higher crude charge rates. Yet, in many cases, all this can be accomplished with relatively modest investment.

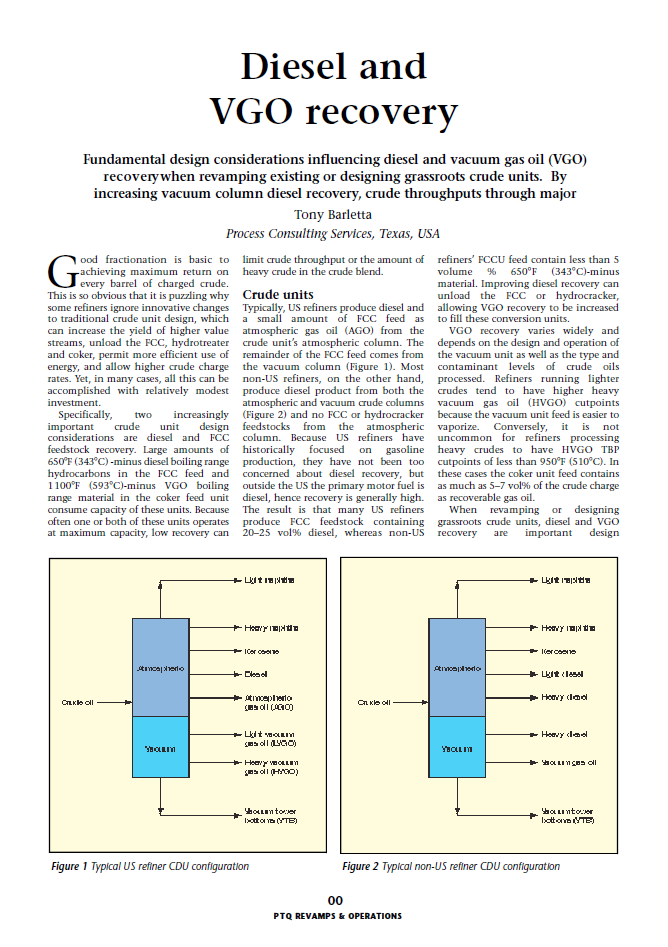

Specifically, two increasingly important crude unit design considerations are diesel and FCC feedstock recovery. Large amounts of 650⁰F (343⁰C) -minus diesel boiling range hydrocarbons in the FCC feed and 1100⁰F (593⁰C) -minus VGO boiling range material in the coker feed unit consume capacity of these units. Because one of both of these units operates at maximum capacity, low recovery can limit crude throughput or the amount of heavy crude in the crude blend.

Typically, US refiners produce diesel and a small amount of FCC feed as atmospheric gas oil (AGO) from the crude unit’s atmospheric column. The remainder of the FCC feed comes from the vacuum column. Most non-US refiners, on the other hand, produce diesel product from…