Centrifugal Compressor Operations

SUMMARY

The wet gas compressor is used as an example in this article reviewing compressor performance, operating conditions and basic control philosophy - an aid to understanding the interactions influencing compressor performance and control.

TEXT

Understanding the interaction between fundamental principles of centrifugal compression, operating changes that influence compressor performance and basic control is important. Since the wet gas compressor plays a central role in FCC operations, it will be used to review compressor performance fundamentals, common operating conditions that influence operations and basic control philosophy.

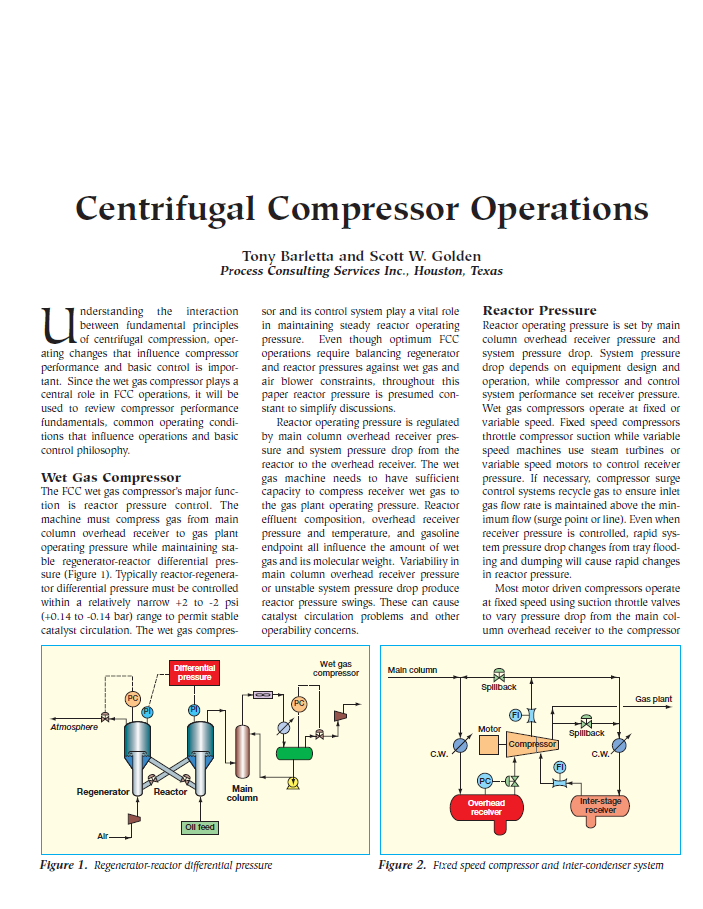

The FCC wet gas compressor’s major function is reactor pressure control. The machine must compress gas from main column overhead receiver to gas plant operating pressure while maintaining stable regenerator-reactor differential pressure. Typically reactor-regenerator differential pressure must be controlled within a relatively narrow +2 to -2 psi (+0.14 to -0.14 bar) range to permit stable catalyst circulation. The wet gas compressor and its control system play a vital role in maintaining steady reactor operating pressure. Even though optimum FCC operations require balancing regenerator and reactor pressures against wet gas and air blower constraints, throughout this paper reactor pressure is presumed constant to simplify discussions.

Reactor operating pressure is regulated by main column overhead receiver pressure and system pressure drop from the reactor to the overhead receiver. The wet gas machine needs to have sufficient capacity to compress receiver wet gas to the gas plant operating pressure...