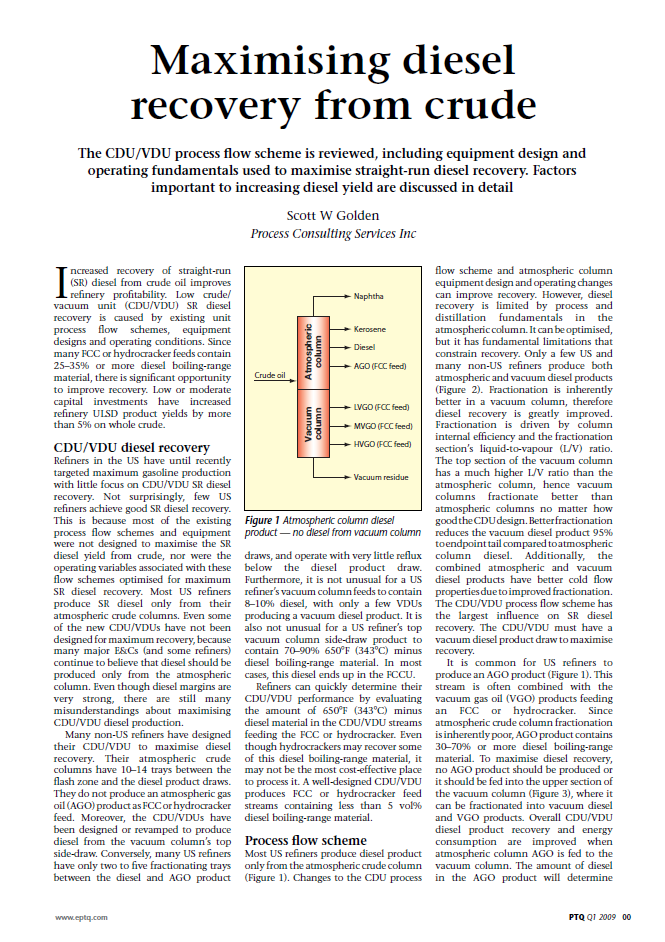

The CDU/VDU process flow scheme is reviewed, including equipment design and operating fundamentals used to maximise straight-run diesel recovery. Factors important to increasing diesel yield are discussed in detail.

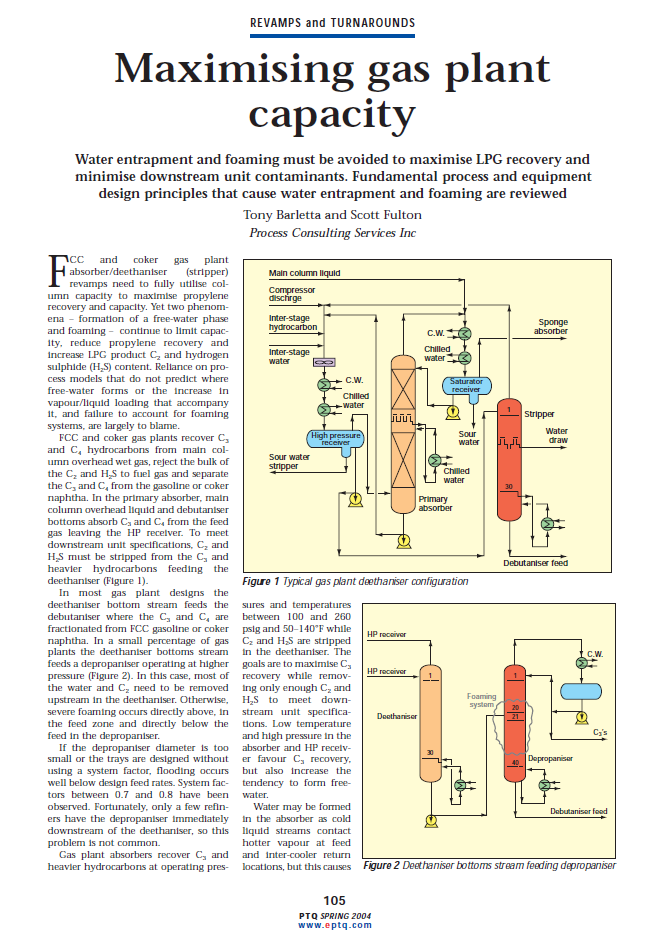

Read MoreWater entrapment and foaming must be avoided to maximize LPG recovery and minimize downstream unit contaminants. Fundamental process and equipment design principles that cause water entrapment and foaming are reviewed.

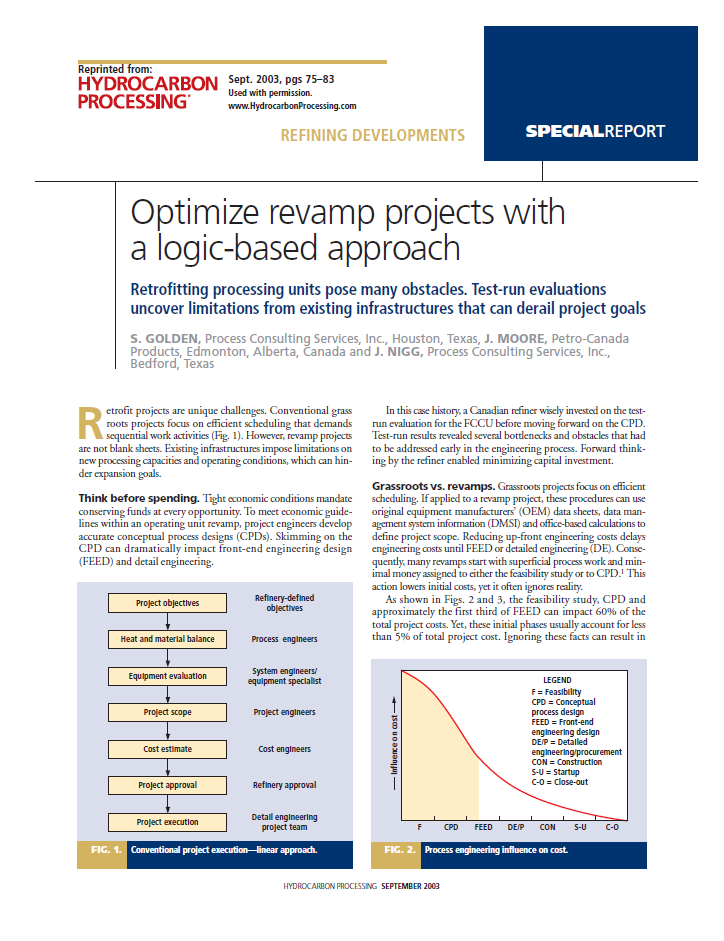

Read MoreRetrofitting processing units pose many obstacles. Test-run evaluations uncover limitations from existing infrastructures that can derail project goals.

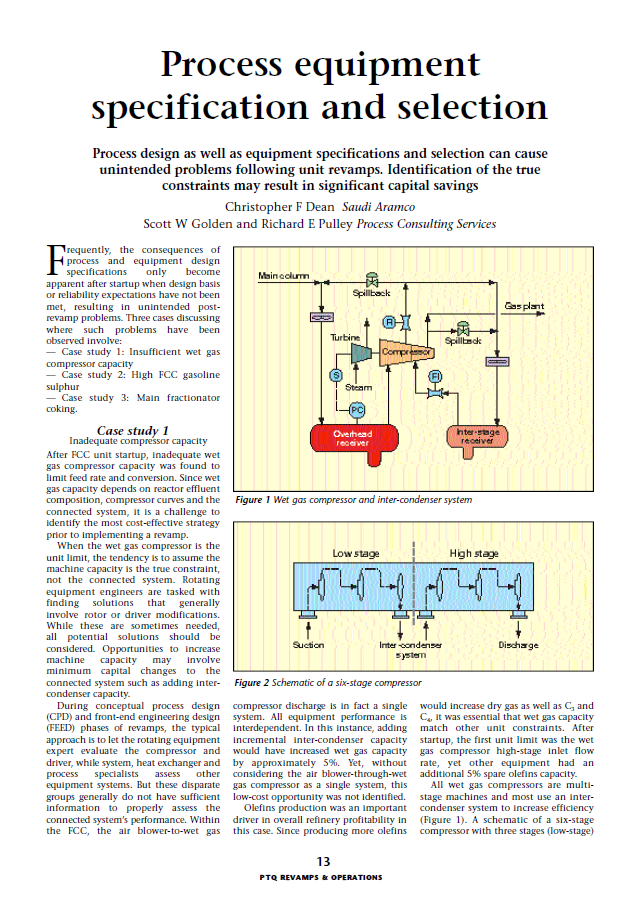

Read MoreProcess design as well as equipment specifications and selection can cause unintended problems following unit revamps. Identification of the true constraints may result in significant capital savings.

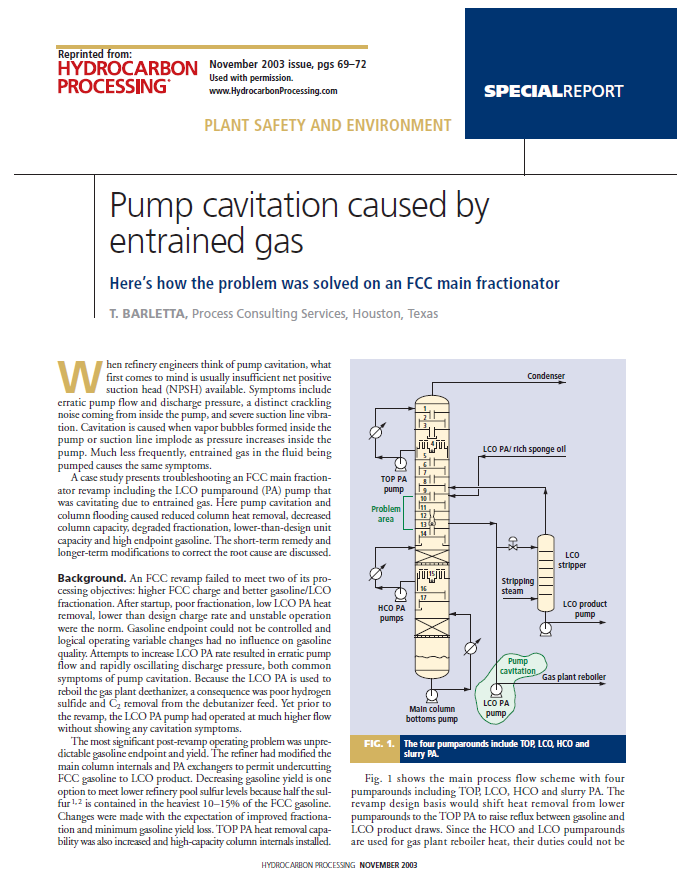

Read MoreHere’s how the problem was solved on an FCC main fractionator.

Read MoreA refiner producing various grades of asphalt from Boscan crude revamped their CDU to maximize asphalt yield while meeting product quality. These heavy crudes are difficult to process and specifications can be challenging when producing performance grade material. The successful revamp detailed in this article increased asphalt yield by 2% on whole crude and greatly improved unit stability.

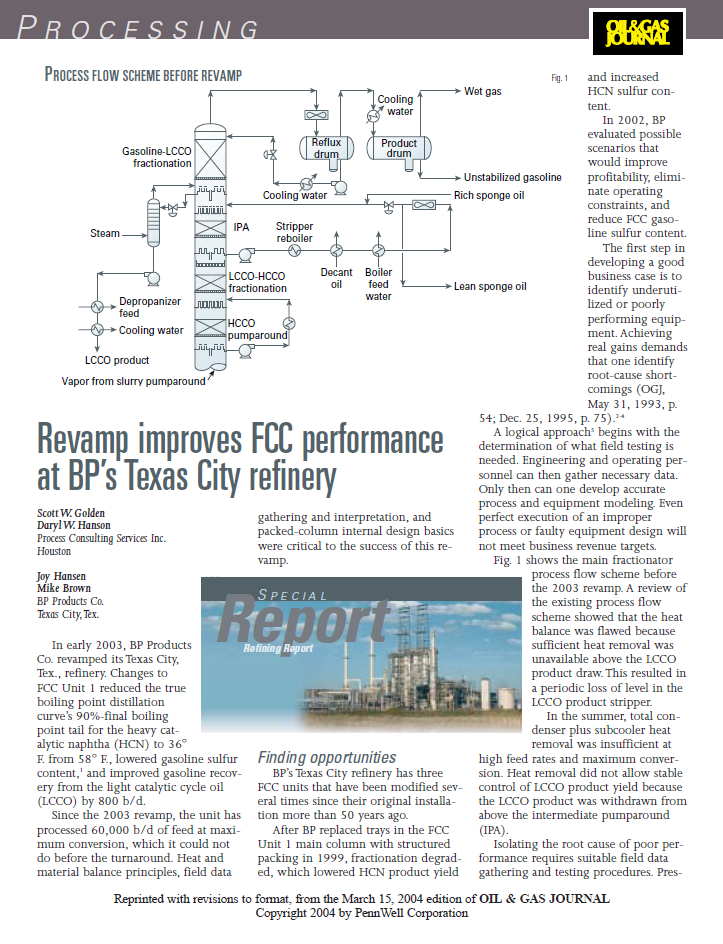

Read MoreBP Texas City revamped their No. 1 FCC main fractionator to improve fractionation, reduce pressure drop and lower naphtha sulfur content. Following the revamp the unit was able to increase capacity and operate at maximum conversion. Careful pre-engineering data gathering and the application of solid engineering fundamentals were critical to the success of this revamp.

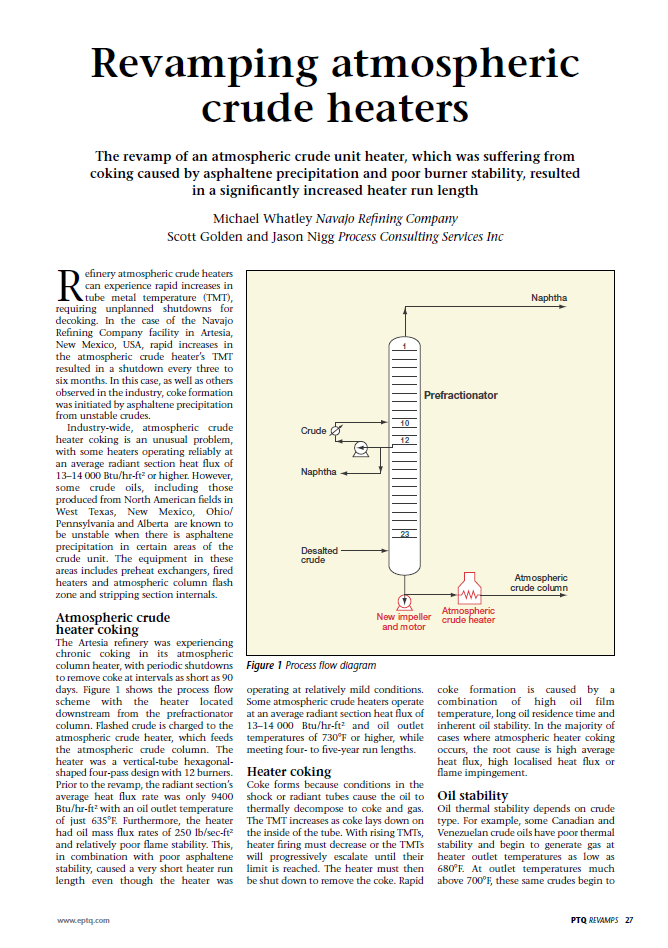

Read MoreThe revamp of an atmospheric crude unit heater, which was suffering from coking caused by asphaltene precipitation and poor burner stability, resulting in a significantly increased heater run length.

Read MoreWith desirability of getting the maximum use out of existing equipment when revamps are planned - not least to minimise investment costs - a rigorous approach to CPD is required to avoid scope growth.

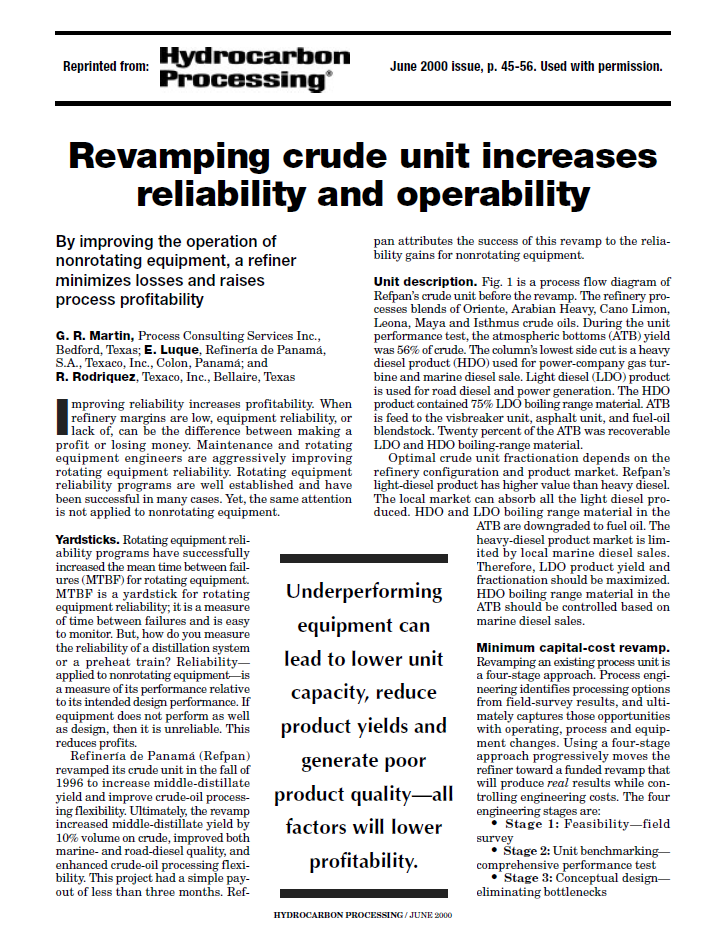

Read MoreBy improving the operation of nonrotating equipment, a refiner minimizes losses and raises process profitability.

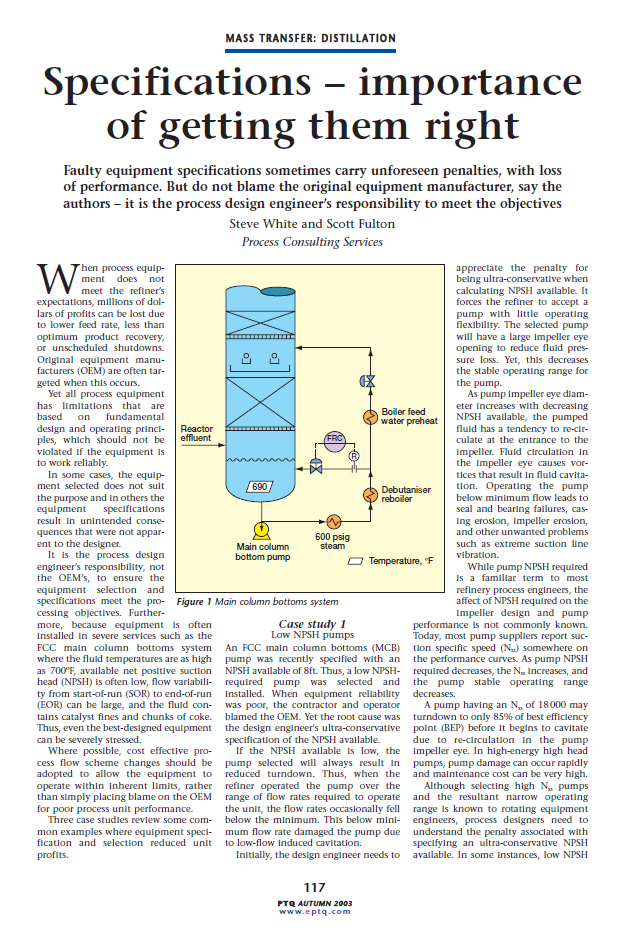

Read MoreFaulty equipment specifications sometimes carry unforeseen penalties, with loss of performance. But do not blame the original equipment manufacturer, say the authors- it is the process design engineer's responsibility to meet the objectives.

Read MoreBasic heat exchange principles are used to explain gas plant thermosiphon reboiler hydraulic constraints. Field measurements help clarify "off-design" operations that were not apparent and were causing high condensate levels.

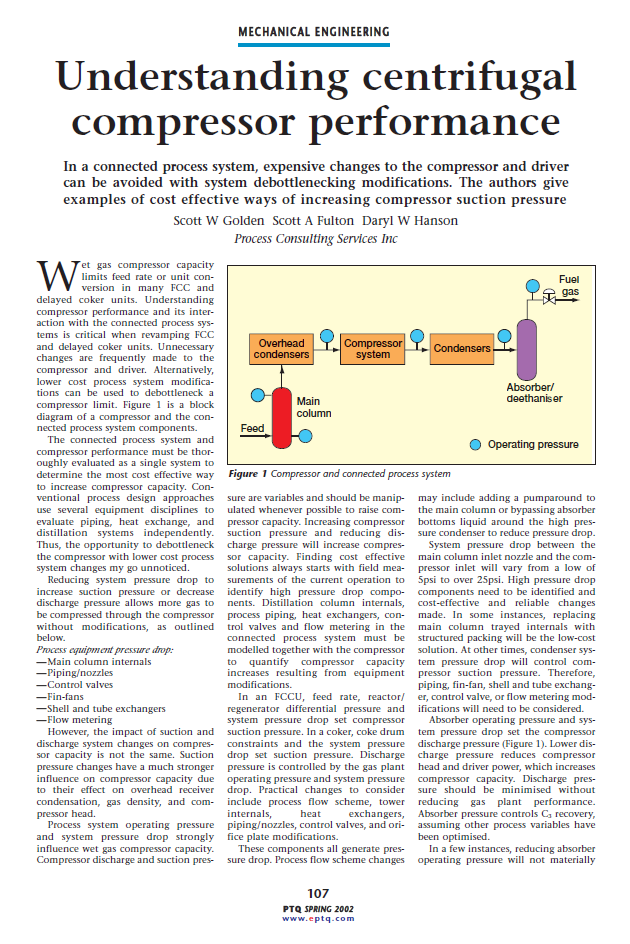

Read MoreUnderstanding how FCC and Delayed Coker wet gas compressor capacity is impacted by system pressure drop allows low cost changes to be made without expensive compressor modifications. In many instances high pressure drop caused by poor system design reduces unit capacity, lowers conversion, or raises column operating pressure. This article presents several solutions for increasing compressor capacity through inexpensive process system modifications.

Read MoreFCC pressure balance is one of the key operating parameters that set catalyst circulation, unit charge rate, and conversion. Quantifying the individual system component pressure drops and the relative cost of reducing them allows cost-effective revamps to be implemented. Several examples present the benefits from actual revamps, which have increased unit capacity by 12%-40%.

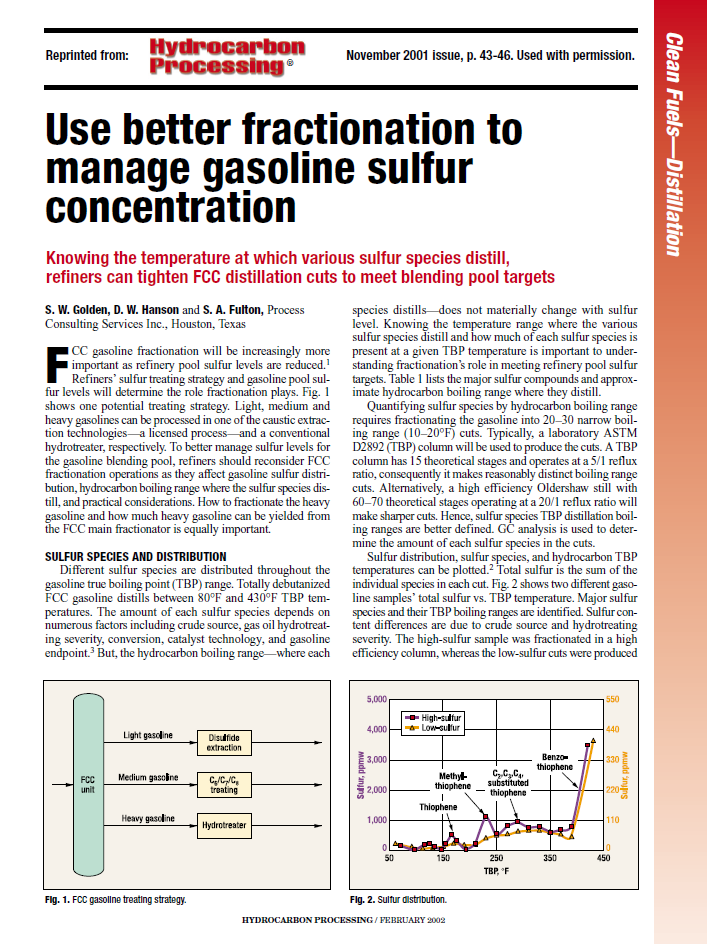

Read MoreKnowing the temperature at which various sulfur species distill, refiners can tighten FCC distillation cuts to meet blending pool targets.

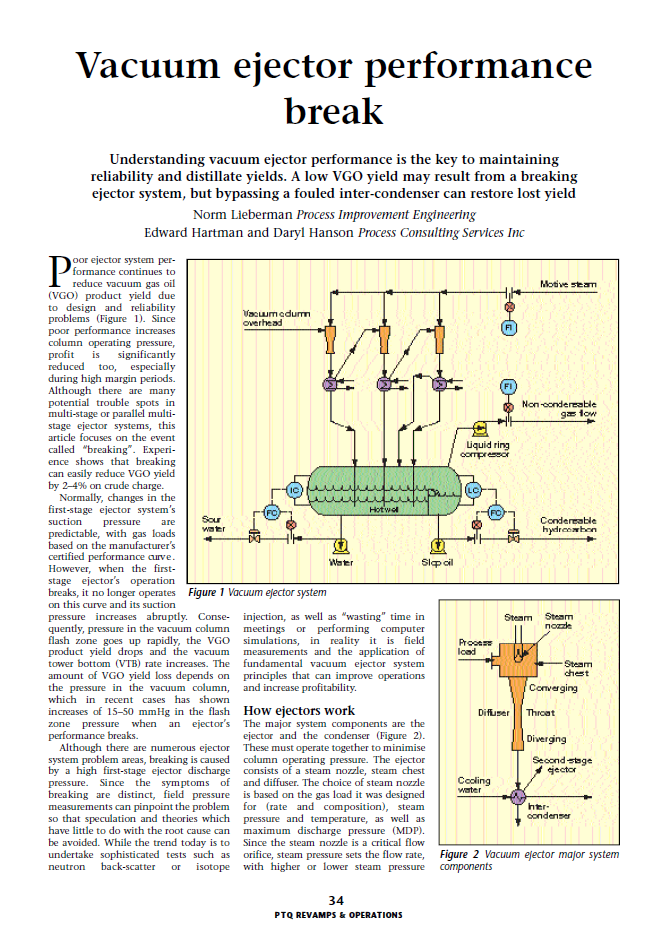

Read MoreUnderstanding vacuum ejector performance is the key to maintaining reliability and distillate yields. A low VGO yield may result from a breaking ejector system, but bypassing a fouled inter-condenser can restore lost yield.

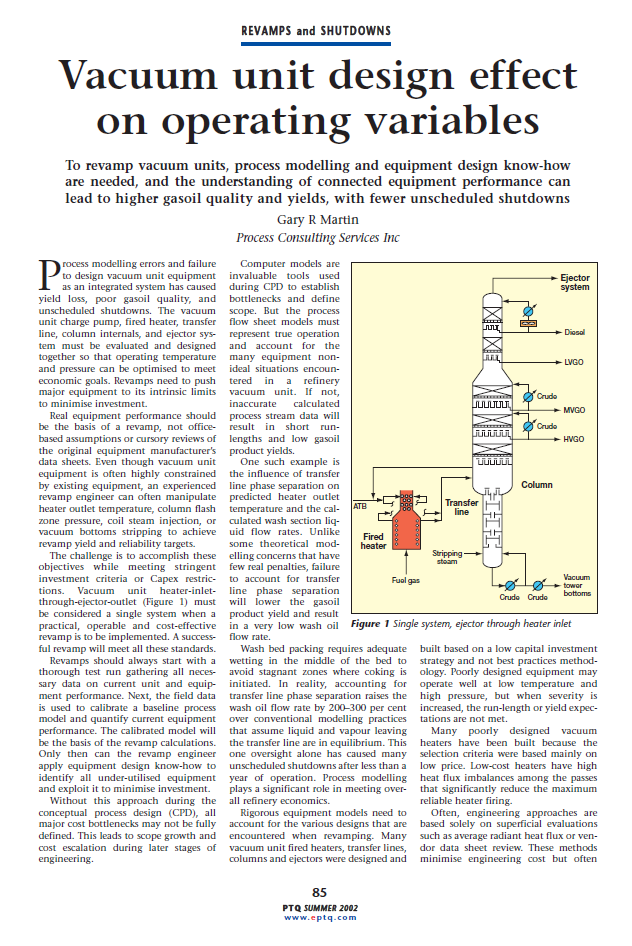

Read MoreTo revamp vacuum units, process modelling and equipment design know-how are needed, and the understanding of connected equipment performance can lead to higher gasoil quality and yields, with fewer unscheduled shutdowns.

Read MorePoor heater design leads to unscheduled Vacuum Unit fired heater shutdowns due to coke formation. Oil film temperature and residence time are the variables that determine the rate of coking for a given crude oil blend. Proper heater design and operation controls oil residence time and oil film temperature, allowing refiners to maximize heater run length.

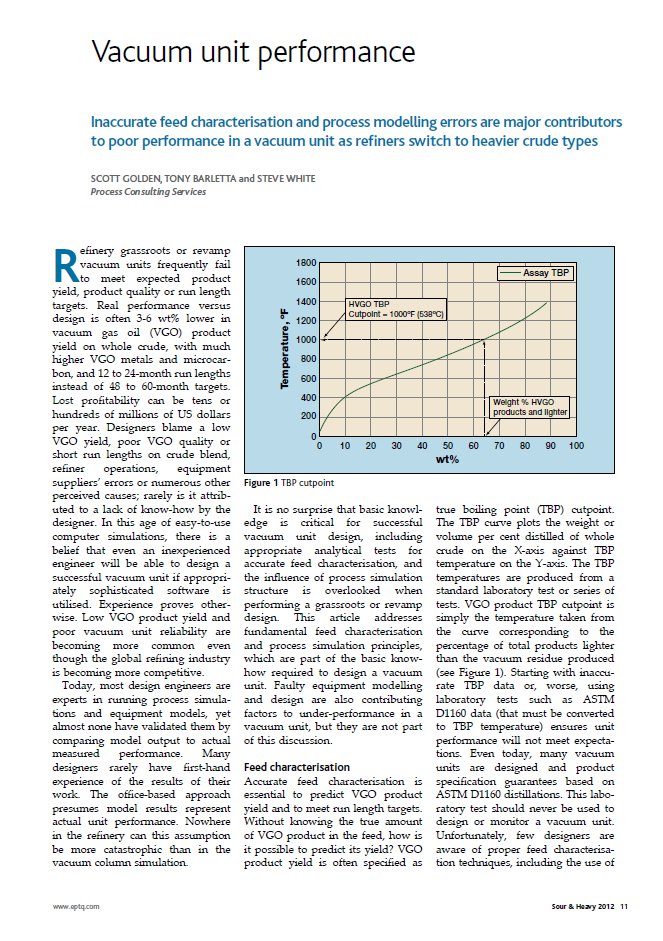

Read MoreInaccurate feed characterisation and process modelling errors are major contributors to poor performance in a vacuum unit as refiners switch to heavier crude types.

Read MoreGood vacuum column pressure control is essential to a successful revamp when vacuum column diameter is the primary unit limit. Poor pressure control can lead to massive entrainment of VTB into HVGO. This is especially significant with heavy crudes with high metals and carbon residue, where entrainment causes a rapid rise in the metals and carbon residue of the HVGO product. This article primarily addresses controlling vacuum column flash zone pressure through the design and operation of the first stage ejector pressure control system.

Read More