Vacuum Ejector Performance Break

SUMMARY

Understanding vacuum ejector performance is the key to maintaining reliability and distillate yields. A low VGO yield may result from a breaking ejector system, but bypassing a fouled inter-condenser can restore lost yield.

TEXT

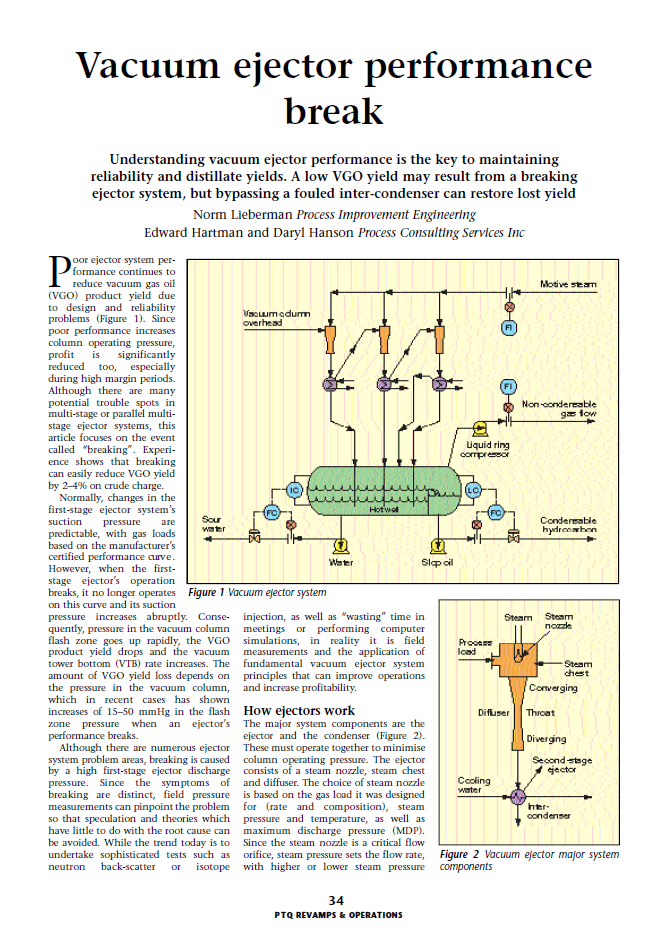

Poor ejector system performance continues to reduce vacuum gas oil (VGO) product yield due to design and reliability problems. Since poor performance increases column operating pressure, profit is significantly reduced too, especially during high margin periods. Although there are many potential trouble spots in multi-stage or parallel multi-stage ejector systems, this article focuses on the event called "breaking". Experience shows that breaking can easily reduce VGO yield by 2-4% on crude charge.

Normally changes in the first-stage ejector system's suction pressure are predictable, with gas loads based on the manufacturer's certified performance curve. However, when the first-stage ejector's operation breaks, it no longer operates on this curve and its suction pressure increases abruptly. Consequently, pressure in the vacuum column flash zone goes up rapidly, the VGO product yield drops and the vacuum tower bottom (VTB) rate increases. The amount of VGO yield loss depends on the pressure in the vacuum column, which in recent cases has shown increases of 15-50 mmHg in the flash zone pressure when an ejector's performance breaks.

Although there are numerous ejector system problem areas, breaking is casued by a high first-stage ejector discharge pressure. Since the the symptoms of breaking are distinct, field pressure measurements...